Aluminum ladders have become a necessity in our daily lives, especially when working aloft. Not only are they essential to professional construction workers to finish their job, in today’s world where DIY is common, they are also necessary for general household projects like painting house walls and fixing common home appliances.

Our society has seen too many accidents related to ladders, especially in the construction industry where they are frequently used. Most of these accidents can be attributed to falls caused by misuse, which takes more than 10 lives in Taiwan every year and results in countless minor and severe injuries. The safety concerns of stepladders have a great impact on the users’ livelihood and safety. But how do we make ladders safer and easier to use by changing their designs?

According to the statistics provided by the Occupational Safety and Health Administration under the Ministry of Labor, more than 10 people were killed every year due to misuse of ladders from 2011 to 2013. More than half of these deaths were caused by falls and the second major cause was electric shock. Causes of falls included improper use, unstable set-up, loss of balance, and slip when climbing up or down the ladder.

DESIGN OPPORTUNITY

Apart from user negligence, inappropriate set-up, “walking” the ladder, limited working area up the ladder, and slip when climbing up or down the ladder are also major causes of ladder-related injury and death. Now we are ruling out the negligence factor from the causes and trying to find the core of the problem and crack it down. We hope our efforts will eliminate the problems we see in ladders on the market.

DESIGN OBJECTIVES

- Increasing the contact area of the ladder and the floor.

- Providing more working area up the ladder, and reducing the climbing count.

- To be easier to store and carry around.

SAFETY RULES

Stepladders are a product that come with risks. Therefore, there are specific and statutory conditions for the designing of stepladders to make sure that stepladder designers and manufacturers are doing their work according to regulations.

The distance between steps should not exceed 30 cm, and the length and width of each step should be more than 30 cm and 5 cm, respectively. The top cap should be more than 12 cm wide. The feet should be armed with anti-slip safety shoes.

1. Sturdy structure made of materials without obvious damages and corrosion.

2. The angle of the feet and ground should be less than 75°. The front side rails and the back side rails should be secured by spreaders.

3. Steps should have a safe surface.

4. If the workplace is more than 200 cm high, a scaffold should be constructed and used with the stepladder.

WERNER PERFORMANCE SYSTEM

LADDER GRADE

• Type III

• Type II

• Type I

• Type IA

• Type IAA

Economical design for lightweight use.

Basic design for simple projects.

Designed to handle most projects and jobs.

Rugged performance designed with the pro in mind.

Maximum performance for the toughest jobs.

STRESS ANALYSIS

Safety is always the most important part in stepladders. The structure and design of the Loop Ladder are distinctive compared to those of other products on the market. Its innovative design requires a structure that can withstand various strength tests. To accomplish this, we’ve conducted a stress analysis to calculate the strength and safety of the structure and determine its feasibility.

According to the Werner Performance System, there are five duty ratings for stepladder load capacity: Household, commercial, professional, industrial, and heavy industrial. Each rating has its own load capacity standard. Stepladders used by construction workers should at least have a professional rating with the load capacity of 113kg. Load capacity is calculated as the sum weight of the user and all tools carried.

To meet the load capacity requirement, we have made numerous adjustments and modifications. The Loop Ladder now has a load capacity of 113kg and is made of 6061 aluminum. The safety latch is made of high-strength steel to avoid bending because it has to support the weight of the stepladder.

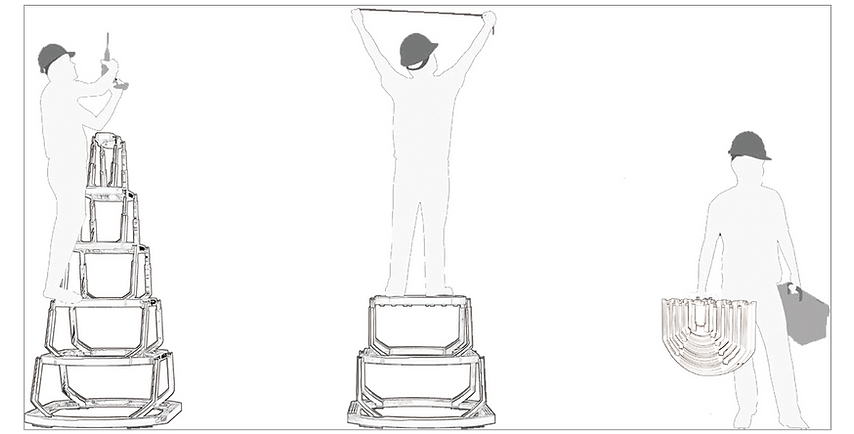

Collapse structure

The collapsing of the steps is achieved by using slide rails, rope and safety latch to transform the whole ladder into a flat device. To collapse the Loop Ladder, simply pull the switch under the steps to trigger the rope and safety latch.

To lay the Loop Ladder down, pull the switch under it.

The switch affects the ropes of tenons on Loop Ladder which is designed to lay it up or out.

Loop Ladder will follow the slide rail to be fold up.